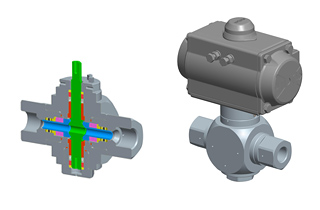

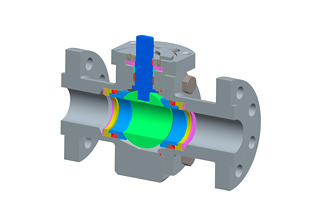

Bottom drain ball valves

Features and advantages of the Perrin design

- Ball valve to vessel adapted to vessel bottom / block flange

- Full passage without any reduction

- Due to the larger inlet flange (usually 2 DN) and the special design, the ball can shut off directly at the tank bottom, above the ball the area is dead space minimized

- Dead space free design below the ball due to the use of a single-seated sealing system

- Good cleaning possibilities due to the single-seat sealing system and the additional use of flushing connections

- Soft-, hard- and metallic sealing seat systems allow the use under different operating conditions

- Due to the use of different metallic materials for body and internal parts (carbon steels, stainless steels, duplex steels, Hastelloy, Monel, Inconel, titanium or similar) the ball valves are suitable for shutting off a wide range of media

- The use of various metallic coatings through in-house production with the latest coating technology means that even abrasive and corrosive solids can be shut off with these container ball valves

- Vacuum tightness due to special spring-loaded seat system is given

- The ball valve design with bearings means that the ball valves have low torques and are also suitable for high switching frequenciesSpecial constructions

- By flattening the ball and using mandrels, the breaking up of crystallizing media is made possible

- By installing an inclined control shaft or using articulated couplings, larger drives can also be attached to the container outlet without colliding with the container

Ball valves in the power plant area

Vorteile von Perrin Kugelhähnen in der Kraftwerkstechnik

- KTA approval for use in nuclear facilities.

- Preparation of preliminary testing documents and calculations (e.g. earthquake calculations) by our own team of design engineers and specially trained persons in the documentation department

- The use of various metallic coatings through in-house production with state-of-the-art coating technology enables solutions for power plant applications with abrasive and corrosive solids as well as in the high-pressure and high-temperature range

- Soft, hard and metallic sealing seat systems enable use in power plant applications under a wide range of operating conditions

Get here our short brochure about Perrin ball valves in conventional and nuclear power plants.

- By using different metallic materials for body and internal parts (carbon steels, stainless steels, duplex steels, Hastelloy, Monel, Inconel, titanium or similar), the ball valves are suitable for shutting off a wide range of media in power plants

- Examples of Perrin power plant applications include:

– Nuclear plants

– DeNOx plants

– Ball valves for FGD

– Ball valves in steam and water circuits

– Ball valves in conventional or fluidized bed firing systems

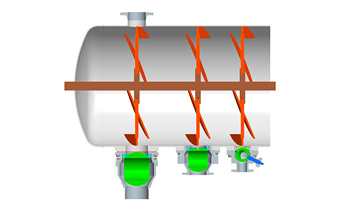

– Ball valves in tank farms

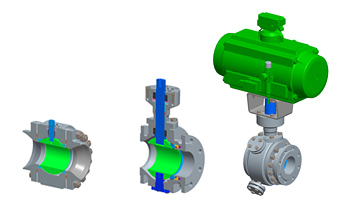

Ball valves for PE/PP production

Advantages of Perrin ball valves for use in PE/PP production lines

- Special PE/PP solids-suitable seat systems.

- Up to 1 million switching operations for solids discharge ball valves due to robust design with one-piece ball switching shaft, stable switching shaft bearings and high-quality seat materials

- Half-shells in various materials prevent polymerization and caking in the dead space

- Soft-, hard- and metal-sealing seat systems enable use under a wide range of operating conditions within PE/PP production

- use of various metallic coatings through in-house production with the latest coating technology enables solutions for applications in the PE/PP solids range as well as in the high-pressure range

- Due to the use of different metallic materials for body and internal parts (carbon steels, stainless steels, duplex steels, Hastelloy, Monel, Inconel, titanium or similar) the ball valves are suitable for shutting off a wide variety of media in the PE/PP range

- Decades of experience with various licensors (e.g. Novolen®, Spheripol® (Basell), Borstar® (Borealis), Unipol®)

Examples of Perrin ball valve applications in the PE/PP field

– Shut-off of PE/PP or their reactants, especially suitable in suspension applications

– Solids discharge ball valves

– Multi-way distribution ball valves

– Metering ball valves (continuous, discontinuous) for catalyst feed (see also separate tab “Metering ball valves”)

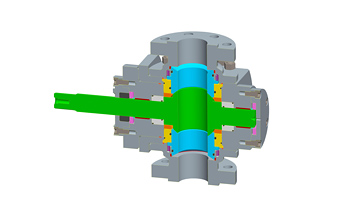

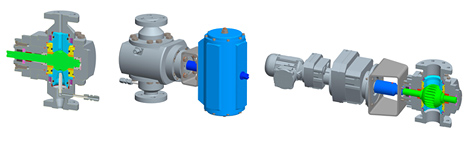

Metering ball valves

Advantages of Perrin ball valves for use in PE/PP production lines

Features and advantages of the Perrin design

- Discontinuous or continuous design depending on application / operating condition.

- Defined volume is introduced into the process

- space filled with half shells

- Soft- hard- and metallic sealing seat systems allow the use under different operating conditions

- By using different metallic materials for body and internal parts (carbon steels, stainless steels, duplex steels, Hastelloy, Monel, Inconel, Titanium or similar) the ball valves are suitable for dosing a wide range of media

- Due to the use of different metallic coatings by in-house production with the latest coating technology, even abrasive and corrosive solids can be dosed with these ball valves

- The ball valve design with bearings and the one-piece ball switching shaft design means that the ball valves have low torques and are also suitable for very high switching frequencies / revolutions

Prinzip des diskontinuierlichen Dosierkugelhahns

- Kugelausführung geschlossen als Tasse mit definiertem Tassenvolumen

- 180° Schaltweg

- Regelung des zu dosierenden Volumenstroms über das Tassenvolumen und die Taktfrequenz

- Tassenvolumen kann durch Tasseneinsätze variiert werden

Prinzip des kontinuierlichen Dosierkugelhahns

- Kugelausführung enthält Schlitze in der Oberfläche mit definiertem Volumen

- Kontinuierlicher Betrieb über Motoransteuerung

- Regelung des zu dosierenden Volumenstroms über das Schlitzvolumen in der Kugel und der Geschwindigkeitseinstellung des Motors

Ball valves for mining applications

Features and advantages of the Perrin design

- Robust design with “heavy duty drive connection flange” for transmitting the high torques in solid applications

- The special design of the spring-loaded seat system on both sides with disc springs prevents solids from sticking between the ball and seats and in the spring area

- The shear edge on the seat ring shears off stuck material during the shifting process

- Full passage without any reduction, thus low pressure loss and low wear

- By using different metallic materials for body and internal parts (carbon steels, stainless steels, duplex steels, Hastelloy, Monel, Inconel, titanium or similar), the ball valves are suitable for shutting off a wide range of media

- By using different metallic coatings through in-house production with state-of-the-art coating technology, the abrasive and corrosive solids can be safely shut off with our mining ball valves. Depending on the application, our metallic coatings are used only in the ball seat area or additionally in the entire ball passageway

- Examples of Perrin applications within mining applications are:

– Ball valves at pump stations

– Ball valves at throttling stations

– Ball valves at isolation stations

Detailed information or quotations on designs for your applications are available on request from: intsales@kitz-eu.com.