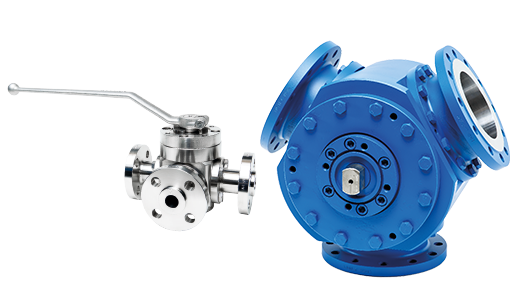

Multi-Way Ball Valves

Floating or Trunnion mounted design

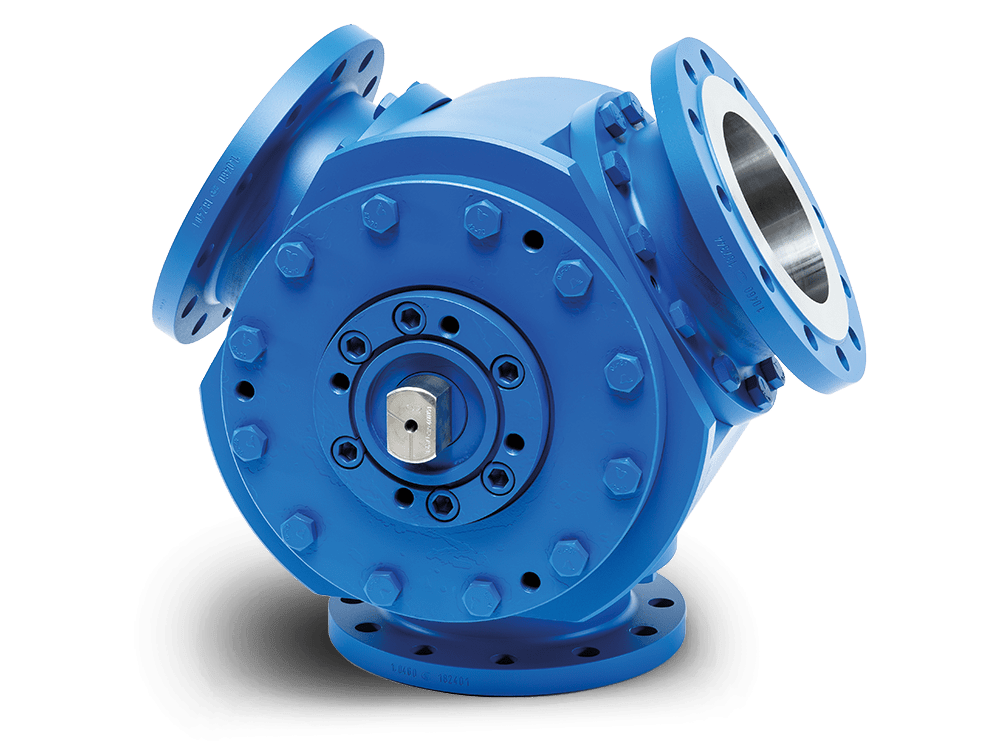

Multi-Way Ball Valves

Trunnion mounted design

The trunnion mounted multi-way Ball Valves are equipped with a 2-component or 3-component body. Springloaded seats are used for sealing. Due to the absorption of force by the trunnion and stem the trunnion mounted Ball Valve not only has less torque than the floating versions, but is also suitable for larger sizes and higher pressure levels. The ball and stem are made in one piece, so that even with a high switching frequency, no slackness and resulting wear can occur on these components’ connectors. The balls are equipped with different bores (e.g. L, T or X) depending on the model, so customized solutions for the distribution of media are available.

MULTIWAY BALL VALVES

Floating design

The 3-way Ball Valves with a floating ball are designed with a 2-component or multi-component body. The floating ball design creates tightness on the downstream side, which keeps increasing as the up-stream pressure continues to rise. The balls are available with an L or T bore.